Features

-

Customer-centered Solution

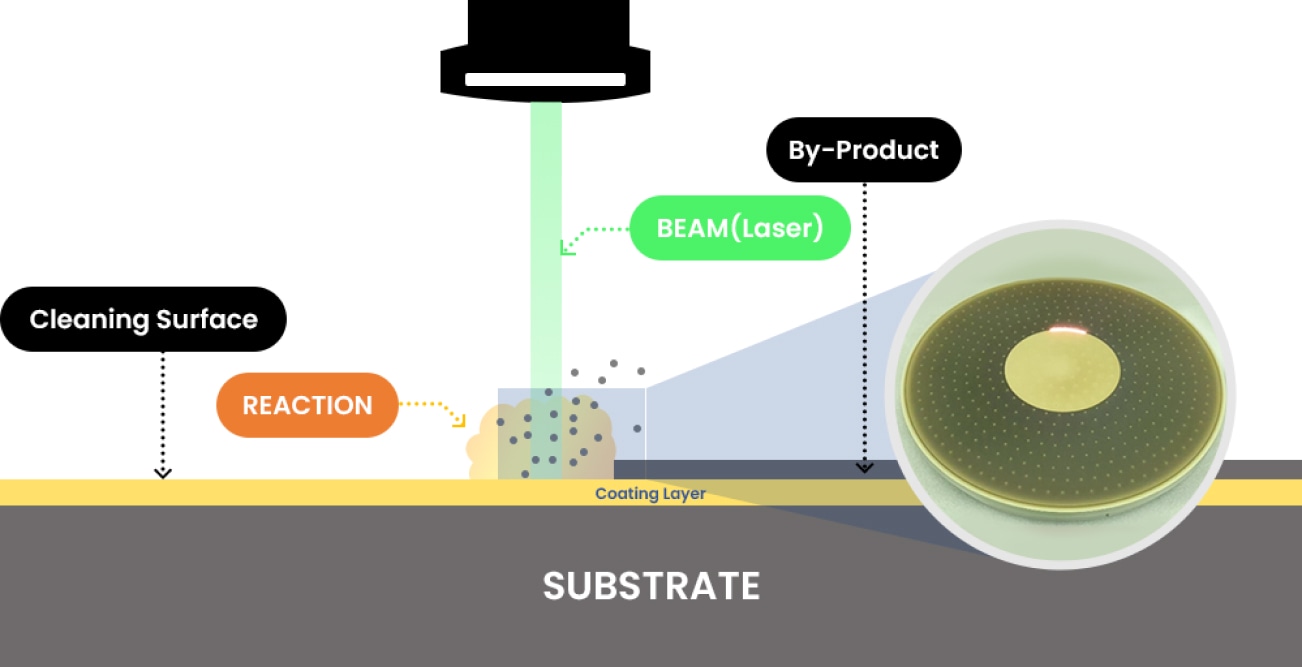

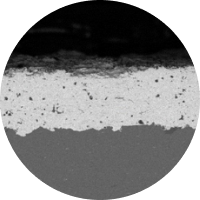

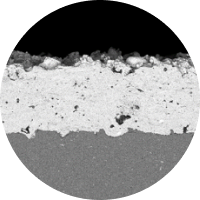

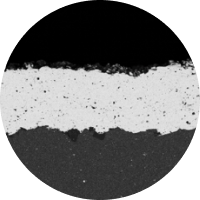

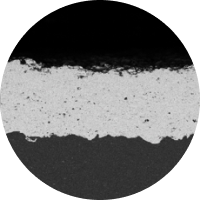

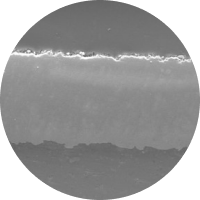

- Providing tailored cleaning and coating technology through the quality management system

- Using MES and a measurement/analysis system to achieve client satisfaction

- Operating Real Time Monitoring System

-

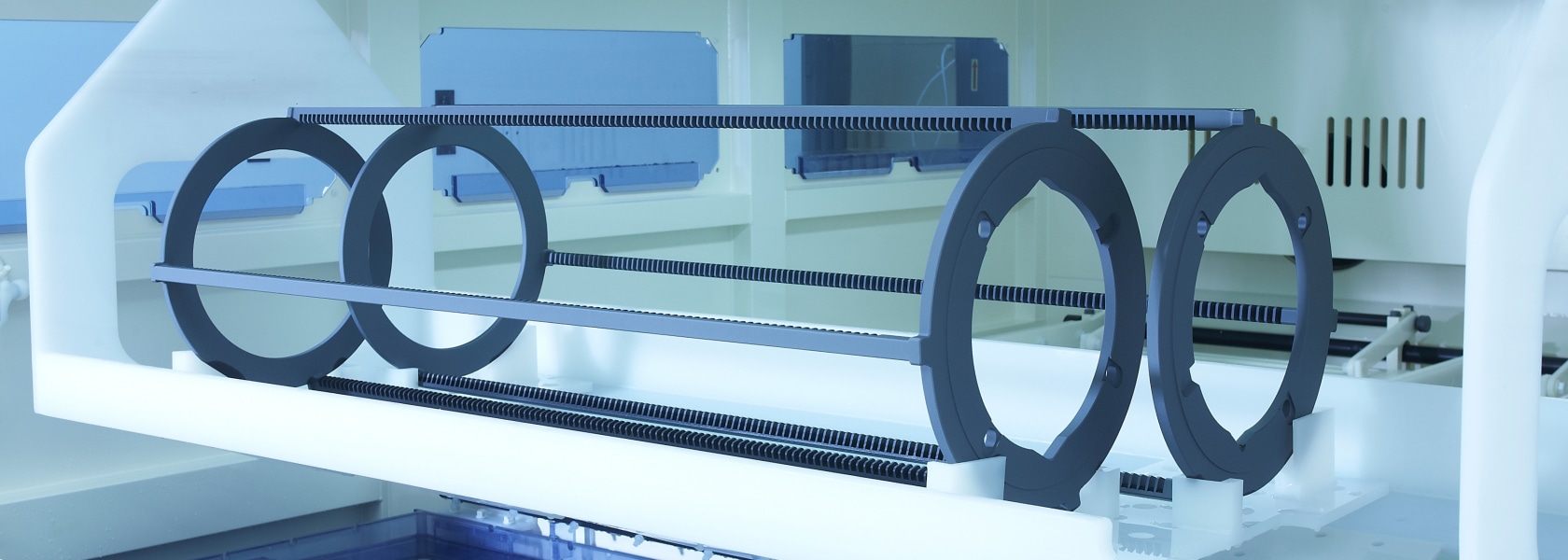

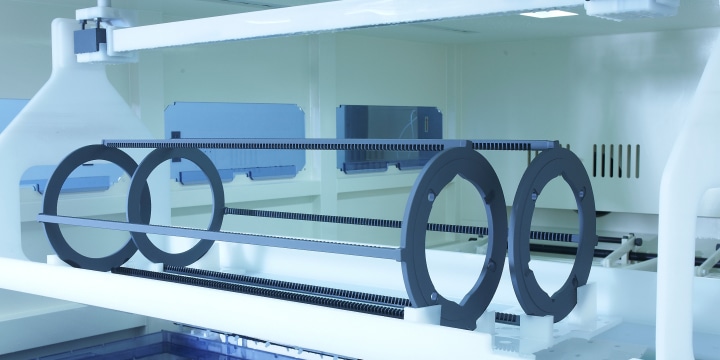

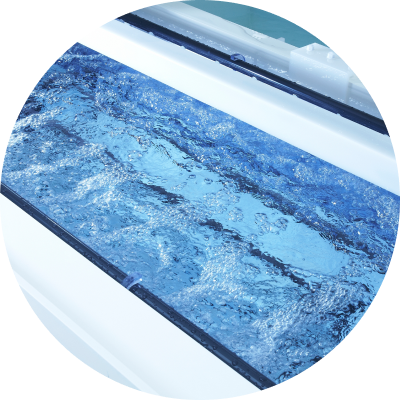

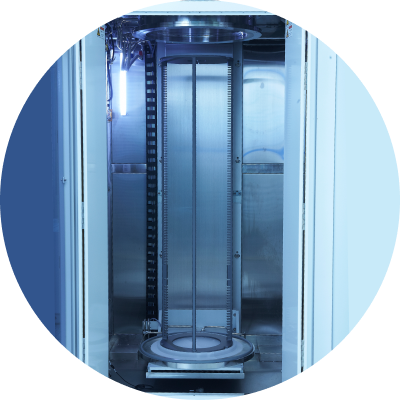

Maximizing our automated cleaning system

- Constructing safe workplaces

- Delivering standardized product quality